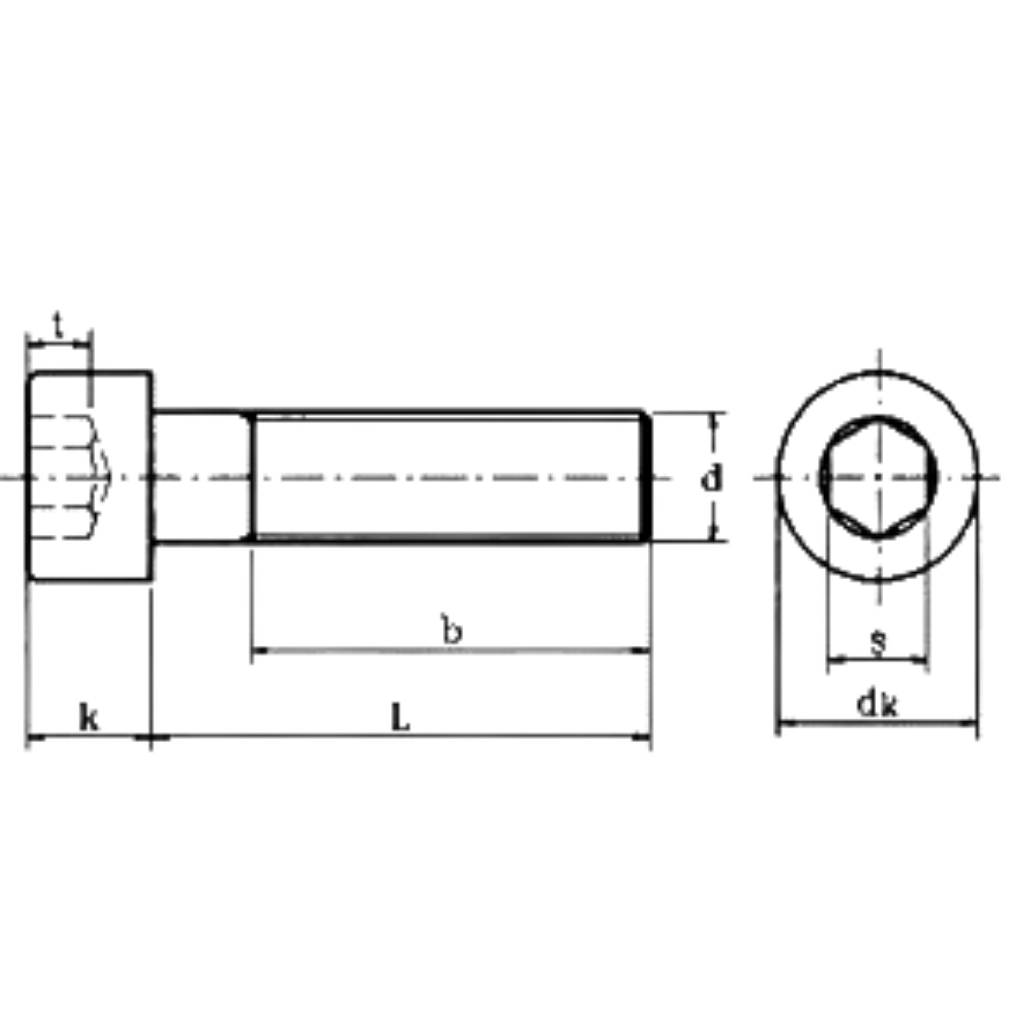

Bolt

12.9 grade bolt made from hardened and tempered alloy steel for maximum strength and durability. Ideal for use in applications with high tensile strength requirements, such as motorsport, heavy industry and machine construction.

These high tensile bolts have a tensile strength of up to 1220 MPa and are surface treated for increased corrosion protection.

Products

1. What does the 12.9 classification on a bolt mean?

The 12.9 grade indicates the bolt’s strength. For 12.9, it means a nominal tensile strength of 1200 MPa and a yield strength of 90% of that, i.e., 1080 MPa.

2. What is the difference between 8.8, 10.9, and 12.9 bolts?

The difference lies in tensile strength:

8.8: Standard bolt for many applications (800 MPa tensile strength)

10.9: For higher requirements, e.g., in vehicles

12.9: Very high strength, used where maximum strength is required, e.g., in motorsport and industry

3. What materials are used for 12.9 bolts?

They are typically made from alloy steel that is hardened and tempered to provide an optimal combination of strength and toughness.

4. Can 12.9 bolts be used in rusty or corrosive environments?

12.9 bolts are not stainless and should be protected in corrosive environments using surface treatment (such as zinc plating) or corrosion inhibitors.

5. Are 12.9 bolts suitable for welding?

No. Due to hardening and alloying properties, 12.9 bolts should not be welded, as this can compromise their mechanical properties.

6. How can a 12.9 bolt be identified?

They are usually marked with the numbers “12.9” on the head according to ISO standard, indicating their strength class.

7. What tightening torque applies to 12.9 bolts?

The torque depends on the bolt’s diameter, pitch, lubrication, and application. It is important to follow a specific torque chart or the manufacturer's recommendations.

8. When should 12.9 bolts be used instead of standard bolts?

When the application requires:

High tensile strength

Compact but strong fastening

Loading in critical components (e.g., cylinder heads, suspension parts, drivetrains)

9. Can 12.9 bolts be reused?

In some cases, yes, but in high-load or safety-critical applications, replacement is recommended after disassembly, especially if the bolts have been stretched to their limit.

|

Bolt Size |

Thread Pitch | Tightening Torque (Dry) | Tightening Torque (Lubricated) |

|---|---|---|---|

| M10x1.5 | Coarse | 83 Nm | 62 Nm |

| M10x1.25 | Fine | 89 Nm | 66 Nm |

| M12x1.75 | Coarse | 145 Nm | 108 Nm |

| M12x1.5 | Fine | 155 Nm | 116 Nm |

| M14x2.0 | Coarse | 230 Nm | 172 Nm |

| M14x1.5 | Fine | 245 Nm | 184 Nm |

Explanations:

- Dry: Bolt is not lubricated – higher friction requires more torque.

- Lubricated: Bolt and nut are greased or oiled – lower friction requires less torque.

- Thread Pitch: Finer threads give more precise control and higher preload at lower torque.

Recommendations:

- Use a calibrated torque wrench for critical applications.

- Use stepped tightening (e.g., 30% – 60% – 100% of final torque).

- Use thread sealant or Loctite where vibration occurs.

- Consider the torque + angle method for even higher precision.

The threaded counterpart (female thread) must be of proper quality – for example:

- Sharp and clean threads, free from damage or debris

- Made from material with sufficient strength (not e.g., raw aluminum without reinforced insert)

- Proper thread depth according to bolt length – generally at least 1x bolt diameter in engaged thread length